Basic Exhaust Manifold Fabrication Needed....

#1

Registered User

Thread Starter

Join Date: Dec 2002

Location: EARTH

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

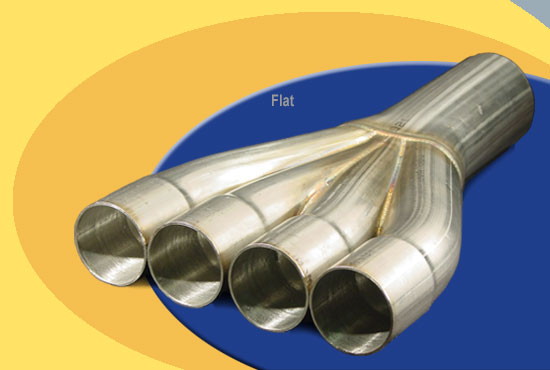

I am looking for someone that can help me make an exhaust manifold for my MR2 project. It is a basic design, but the cuts are too complex for me to even try to tackle with my limited tools and with the way they merge together at the collector. I am in Newport News for reference. If anyone is willing and capable to do this, please let me know. Here is a thrown together pic of what it should look like:

Everything except the head flange is stainless. The head flange is mild steel. I have got to get this done, so any help, or contact info for someone that can do it, is appreciated. Thanks and take care!

Everything except the head flange is stainless. The head flange is mild steel. I have got to get this done, so any help, or contact info for someone that can do it, is appreciated. Thanks and take care!

Last edited by NDISGII; 05-22-2009 at 03:13 PM.

#3

Registered User

Thread Starter

Join Date: Dec 2002

Location: EARTH

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

#4

Registered User

Thread Starter

Join Date: Dec 2002

Location: EARTH

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

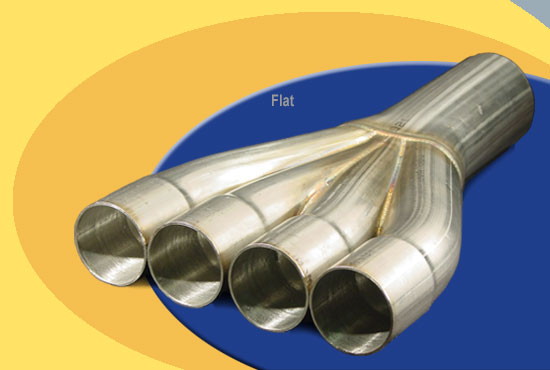

I know it might be hard to see with my pic, but it would be like this one, but a LOT more compact and the runners obviously spread apart more, but the flat design is what I am looking for, so I guess 4 into 1 flat style  :

:

Total measurement from head side of head flange to turbo side of turbo flange must not exceed about 6". I tested the measurements using the (4) 90s and the (4) 45s shown in the pic, and it worked out almost perfect, but I have no way to cut these things or weld them.

:

:

Total measurement from head side of head flange to turbo side of turbo flange must not exceed about 6". I tested the measurements using the (4) 90s and the (4) 45s shown in the pic, and it worked out almost perfect, but I have no way to cut these things or weld them.

#5

Racetracks

Join Date: Nov 2002

Location: How long is a piece of string?

Posts: 15,668

Likes: 0

Received 0 Likes

on

0 Posts

Why not combine the four runners into a square, like most shorty manifolds? What's the reason that you need a flat 4 into 1? That's horribly compromised compared to a square.

#6

Registered User

Thread Starter

Join Date: Dec 2002

Location: EARTH

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

Its not that I am opposed to the standard way of merging, but with the runners being so terribly short, there is no way to get them into position to come into a standard collector without them hitting each other and having to merge before getting there. Hope that made sense...lol...

#7

VAdriven Sponsor

Join Date: May 2005

Location: Virginia Beach

Posts: 4,390

Likes: 0

Received 0 Likes

on

0 Posts

#8

Racetracks

Join Date: Nov 2002

Location: How long is a piece of string?

Posts: 15,668

Likes: 0

Received 0 Likes

on

0 Posts

It's still a bad idea. It's probably fine for short term use if the turbo is properly supported and strain relieved. Stainless and mild steel aren't dissimilar metals in the true sense, but they do have different corrosion potential and thermal expansion. Not something you'd see an OEM doing in the interests of long life, that's for sure. I know there are filler rods that are spec'd for doing this exact thing, but it just seems really sloppy way to do things considering the service temp that this has to survive.

Last edited by Fabrik8; 05-22-2009 at 08:01 PM.

#9

JAY SPEC

Join Date: Sep 2003

Location: Chesapeake/ODU

Posts: 3,170

Likes: 0

Received 0 Likes

on

0 Posts

It's still a bad idea. It's probably fine for short term use if the turbo is properly supported and strain relieved. Stainless and mild steel aren't dissimilar metals in the true sense, but they do have different corrosion potential and thermal expansion. Not something you'd see an OEM doing in the interests of long life, that's for sure. I know there are filler rods that are spec'd for doing this exact thing, but it just seems really sloppy way to do things considering the service temp that this has to survive.

#10

Racetracks

Join Date: Nov 2002

Location: How long is a piece of string?

Posts: 15,668

Likes: 0

Received 0 Likes

on

0 Posts

Well, thermal expansion differences can cause enormous stress at the interface, but that depends a lot on the geometry of the weld and the parts being welded. But yes, there can be huge stress differences across the weld line during thermal expansion, and even during cooling after welding. A piece of metal just sitting there at room temp can still have a lot of stress built up even though you can't see it. I've machined pieces of hot rolled metal stock that have twisted or bent as soon as the outer layer is removed and the stress is allowed to release. You fly cut something to make it really flat, and then it warps when you fly cut it. Weird stuff, and you just have to deal with it. but I digress...

There might be the possibility of galvanic corrosion at the weld line though, which could happen through the entire cross section of the weld (not just the exposed surface). You've got two different metals, with two different galvanic potentials that are being loosely mixed together at the weld line along with some other metal in the filler rod. You also have 3 different melt points for those 3 different metals too. Hard to predict, which is the problem. I'd rather spend the extra money and not have some unpredictable problem at some unpredictable time. I'd make the whole thing out of stainless, or out of mild steel, but not out of both. You're not going to get rusting problems any more than if the whole thing was made of mild steel though; the rust will stay on the exposed surface like normal..

Slip joints in an equal length manifold can help a lot too, but that's another thing that you don't see if you're looking to save money. There is a big difference between good practice and the "fuck it, it's going on a street car" mentality.

Again, as long as there isn't any stress at the weld line, it will probably do just fine. So if the turbo isn't hanging off the manifold and being supported by the flange to head interface, it's probably OK. It's all about supporting the turbo properly but still allowing everything to move on its own so no stresses can build up when things start to move around thermally.

My whole point here is that if welding stainless to mild steel works then that's fine, and you've gotten lucky that you're not doing anything critical enough to make it fail.

Really my concern is not welding dissimilar metals (welding stainless to mild steel isn't uncommon), but rather the service temps that it will see and what that means to the weld life.

There might be the possibility of galvanic corrosion at the weld line though, which could happen through the entire cross section of the weld (not just the exposed surface). You've got two different metals, with two different galvanic potentials that are being loosely mixed together at the weld line along with some other metal in the filler rod. You also have 3 different melt points for those 3 different metals too. Hard to predict, which is the problem. I'd rather spend the extra money and not have some unpredictable problem at some unpredictable time. I'd make the whole thing out of stainless, or out of mild steel, but not out of both. You're not going to get rusting problems any more than if the whole thing was made of mild steel though; the rust will stay on the exposed surface like normal..

Slip joints in an equal length manifold can help a lot too, but that's another thing that you don't see if you're looking to save money. There is a big difference between good practice and the "fuck it, it's going on a street car" mentality.

Again, as long as there isn't any stress at the weld line, it will probably do just fine. So if the turbo isn't hanging off the manifold and being supported by the flange to head interface, it's probably OK. It's all about supporting the turbo properly but still allowing everything to move on its own so no stresses can build up when things start to move around thermally.

My whole point here is that if welding stainless to mild steel works then that's fine, and you've gotten lucky that you're not doing anything critical enough to make it fail.

Really my concern is not welding dissimilar metals (welding stainless to mild steel isn't uncommon), but rather the service temps that it will see and what that means to the weld life.

Last edited by Fabrik8; 05-22-2009 at 10:00 PM.